thickness measurement laser sensor programming|laser sensor thickness measurement : broker This guide is intended to assist the user in setting up (2) Acuity Triangulation Sensors and an Acuity Touch Panel Display for a dual thickness measurement. What you will receive to start . Resultado da 9 de mai. de 2021 · OS SIMPSONS PREVIRAM OS NUMEROS DA MEGA-SENA!!-DEIXA O LIKE--INSCREVA-SE NO CANAL!!-

{plog:ftitle_list}

Welcome to ChatSpin, a random video chat app that makes it easy to meet new people online. ChatSpin offers video chat features including face masks, gender and country .

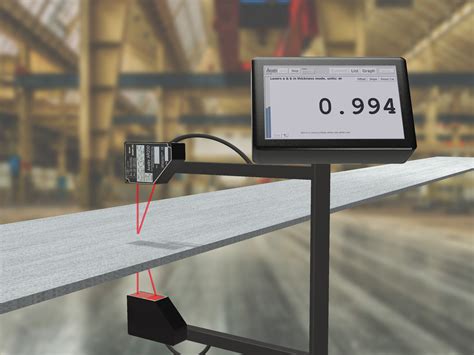

Dual opposed laser sensors measure the thickness of a gauge block. The video explains the setup procedure and tips when using Acuity laser sensors and a Tou.Thickness measurement takes place by arranging P3 series laser triangulation sensors in opposite positions. The P3 sensors use the triangulation method to detect the distance to the . In this video we show an example of a simple thickness measurement setup using our 8-inch Touch Panel Display and two AR700 Laser Displacement Sensors. Non-contact thickness gauges are the devices used to check thickness without physically touching the material. These gauges employ advanced technologies like laser sensors, ultrasonic sensors, or optical .

laser sensor thickness measurement

laser gauge for thickness

This guide is intended to assist the user in setting up (2) Acuity Triangulation Sensors and an Acuity Touch Panel Display for a dual thickness measurement. What you will receive to start . MTI Instruments offers a line of Microtrak laser triangulation sensors that offer high speed, high resolution displacement, position and vibration measurements.Sub-Micron Thickness Measurement with Dual Laser Sensors. In this application video demonstrating sub-micron thickness measurement, we have two of our Acuity Laser AR700 .

Laser triangulation. The Calipro DML optical system uses laser triangulation online to measure the thickness or coating thickness of various materials with the highest accuracy. Product Highlights. Non-contact, non-destructive and ultra .

Thickness measurement of a wide variety of materials using laser triangulation, suitable for both flexible and rigid products.LASER SENSORS FOR DIMENSIONAL VERIFICATION OF LENGTH, WIDTH OR THICKNESS. Laser measuring sensors are commonly used in industry and research for dimensional verification of length, width or thickness. . The .Thickness measurement of a wide variety of materials using laser triangulation, suitable for both flexible and rigid products. DE EN. USA. Worldwide. Search +49-9441-601-0 [email protected]. Home; Company . Laser sensors Laser .

Carbon Black Content Tester convenience store

Synchronous Thermal Analyze convenience store

For remote programming, connect the sensor’s yellow wire to +5 to 30V dc, with a remote programming switch connected between them. The impedance of the remote teach input is 18 k Ω minimum (65 k Ω minimum at 5V). To program the sensor, follow the sequence of input pulses, button pushes, and “clicks” for programming on the sensor buttons .The AR700-8 Laser Displacement Sensors were selected for this measurement due to the range needed and high accuracy of the sensors. The AR700-8 model measures out to 16 inches, with 8 inches of measurement range. At an impressive accuracy of 0.03% of the span at that range, the AR700 was able to meet the precise measurement specs for this application, . This technique for measurement of cake thickness makes use of a He–Ne laser beam and an optical captor; it relies on the absorption of light by the cake. Measurement of the thickness is made at a single point on the membrane and it is assumed that the cake build-up is uniform along the whole area of the membrane. This technique estimates the growth of cake .Acuity engineers selected (2) AR700 – 0125 laser displacement sensors due to the thickness accuracy needed for the copper strips. The AR700-0125 sensors provide a measurement range of up to 0.125 inches while having the ability to be accurate to within 1 micron.

The introduction of CMOS optical displacement sensors has resulted in lower-cost laser displacement sensors that are starting to rival other traditional displacement sensors such as eddy current and capacitive sensors. Laser displacement sensors (see sidebar "The MTI Microtrak II") are also suited to make difficult thickness measurements. For .

The new thicknessSENSOR opens up diverse application possibilities in terms of non-contact thickness measurement. The sensor operates with high precision and enables fast commissioning as well as ease of use. . Long-range laser sensors; Customer-specific sensors; thicknessSENSOR; Characteristics. Measuring ranges: 10 mm | 25 mm; Measuring .The AR700 laser displacement sensor is Acuity’s top of the line, most precise, laser triangulation sensor. The AR700 series contains models with measurement ranges from 0.125 inches up to 50 inches and resolutions as low as one-sixth of a micron.Four-axis laser micrometers measure the outside diameter of a part from four directions. This measurement is achieved with either four single-axis micrometers mounted to a common surface for coplanar measurement or using two dual-axis laser micrometers offset and rotated 45 degrees relative to each other. Note that with two dual-axis micrometers, the measurements .

Measuring the deformation of brake discs under load while braking is an ideal task for the optoNCDT 1700BL. Due to the short wavelength of the blue-violet laser used, the light emitted from the red-hot brake does not dazzle the sensor, as the 600-nm wavelength is a long way off the 405-nm wavelength of the blue-violet laser and is effectively blocked by the high quality .Measuring mechanism: C-frame (for centerline measurement) Sensor type: Two triangulation measuring heads per C-frame for measuring top and bottom side of the strip Laser classification: Laser class 2 acc. DIN EN 60825-1/A1 12.99 Thickness noise (See Note): ± 3 µm Thickness accuracy (See Note): within ± 10 µm regardless of alloy Thickness .Laser triangulation sensor Calipro DML. Non-contacting thickness measurement by means of laser triangulations. Qualiscan QMS-12 Traversing quality control system pdf 6 MB Download Your contact Mr Matthias Wulbeck +49 9441 601 123 .

When selecting sensors to measure thickness or width, the first step is to choose a method. The target's material, colour, and location will all play factors in which option is the best fit for your application. You can browse through the most common setups below, or request a free consultation with a local measurement expert. . 2D/3D Laser .

The QuellTech thickness measurement consists of 2 or more laser line sensors, where 2 laser line sensors 180 Grand are facing each other and the material to be measured passes between them. This solution can be .

The confocal measuring principle enables one-sided thickness measurement of transparent materials such as display glass. This means that only one sensor is required for one measuring point. . Laser displacement sensors arranged .

Based on the property that the absolute zero of an axial intensity curve exactly corresponds to the focus of the objective in a differential confocal system (DCS), a new laser differential confocal lens thickness measurement is proposed to achieve the high-precision non-contact measurement of lens thickness. The proposed approach uses the absolute zero of . A differential miniaturized thickness measurement calibration system based on laser triangulation sensors. July 2023; Journal of Physics Conference Series 2548(1):012020;The Microtrak 3 Thickness Gauge System used for automated metal, fiberboard and cement board sheet production and QA/QC combines our proven non-contact laser triangulation sensors with a modular controller that can operate either as a standalone solution for displacement measurement or with a PLC/PC.. The controller simplifies thickness applications through .

Non-contact thickness measurement can be done during real-time production, such as with copper strip thickness measurement. In this method, product thickness is measured in-line on the production line as the material is being produced. But an alternative to in-line measurement is to use thickness measurement for sheet stack inventory counts.Thickness Measurement; Width Measurement; By Industry Type. Academia, University and Government Research . such as the AR200 Laser Measurement Sensor and the AR700 Laser Displacement Sensor, . terminal includes software for calculating thickness and other dimensions without the need for a computer or software programming. Measuring Battery .

How to Measure Thickness (sheet form) STEP 1: Select whether the shape of the measurement target is a thin sheet or some other shape. STEP 2: Look at the methods outlined in each item to find the best measurement method. STEP 3: Download .

Thermal Conductivity Tester convenience store

Confocal chromatic sensors. The confocalDT sensors product range stands for the highest precision and dynamics in confocal chromatic measurement technology. These sensors enable high-precision and fast measurements for both distance and thickness measurements of transparent objects.BEDFORD, N.H., Oct. 21, 2024 — The 3DS Series from Bold Laser Automation is a confocal thickness measurement system for the measurement of electronics, medical devices, and filtration products. Integrated with Keyence CL Series laser sensors, the system uses continuous in-line and discrete off-line inspection, as well as real-time data plotting and archiving.

of thickness measurement is their non-destructive nature. In this literature review, we will discuss some of the recent developments in the use of ultrasonic sensors for thickness measurement. "Ultrasonic thickness measurement in aluminium using laser generated ultrasonic waves" by M. This study presents a new approach to thickness

Ultra High-Speed/High-Accuracy Laser Displacement Sensor LK-G5000 Series. Product catalogue download; Optical Thrubeam Method TM Series / LS Series. . Thickness measurement is performed by measuring the height of a target as a step height relative to a reference surface.The monitor display area was 1280 pixels wide by 800 pixels high. The thickness measurement sensor system consists of a laser mouse and a lightweight cylindrical displacement probe that is made of steel. To guide the vertical movement of the probe, an open-ended minimum friction tube with a hole is used (Figs. 4–6).

13 de dez. de 2023 · 00:00. 04:19. Os Sacanas - Dormindo com Papai e Mamãe (primeira dublagem) by. TUFOS. Topics. TUFOS. Language. Portuguese. Lost Media/Wave (???) .

thickness measurement laser sensor programming|laser sensor thickness measurement